In this article we will discuss the various types and process involved in welding pipe manufacturing.

Welded steel pipe(also known as welded pipe) is made of steel plate or steel strip after crimping,generally fixed length of 6 meters.Welding pipe production process is simple,high production efficiency,variety specifications, less equipment investment,but generally welded pipe less than the strength of seamless pipe.

In the API 5L standard,there are usually the following welding pipes:

Electric resistance welded (ERW) pipe is manufactured by cold-forming a sheet of steel into a cylindrical shape. Current is then passed between the two edges of the steel to heat the steel to a point at which the edges are forced together to form a bond without the use of welding filler material.Electric resistance weld pipe is normally produced in sizes from 2% inch 00 NPS 2 thru 24 inch 00. (NPS 24)

Electric Resistance Welding Process ERW Pipe Manufacturing

ERW including high frequency welded steel pipe(HFW) and low frequency welded steel pipe(LFW).Over time, the welds of low frequency ERW pipe was found to be susceptible to selective seam corrosion,hook cracks,and inadequate bonding of the seams,so low frequency ERW is no longer used to manufacture pipe.The high frequency process is still being used to manufacture pipe for use in new pipeline construction.

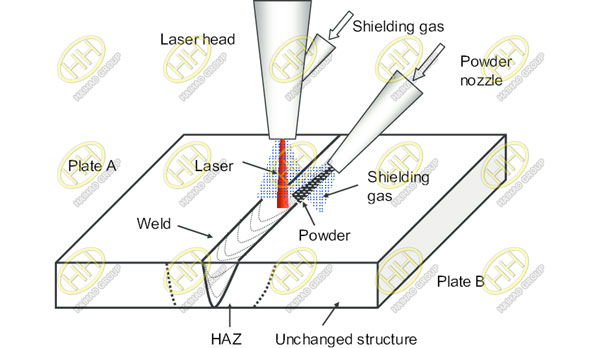

Schematic of laser beam welding process

Laser welding is a non-contact process which requires access to the weld zone from only one side of the parts being welded.Laser welding attributes are particularly important in the production of austenitic,ferritic,and duplex stainless steel used in the automotive,aerospace,food processing,medical,oil and gas,and chemical industries.

Continuous welded pipes,referring to small diameter products manufactured using continuous welding process, are primarily utilized for supply of water and gas at lower costs and higher productivity. Continuous welded pipes are considered as the lowest cost variants among all steel pipes, and find use in structural applications, plumbing applications, and other low pressure applications.Continuous weld pipe is produced in sizes from NPS Va to NPS 4.

Submerged arc welding (SAW) process involves formation of an arc between a continuously fed bare wire electrode and the work-piece.

There are two types of submerged arc welding (SAW) processes:Longitudinal Submerged Arc Welding (LSAW) ,Spiral Submerged Arc Welding (SSAW).

Longitudinal Submerged Arc Welding Process LSAW Pipes Manufacturing

The longitudinal submerged arc welding(LSAW) steel pipe diameter range is larger than ERW,normally from 16 inch to 60 inch, 406mm to 1500mm. Good performances on high pressure resistance,and low-temperature corrosion resistance.

Spiral Submerged Arc Welding Process SSAW Pipes Manufacturing

Spiral submerged arc welding (SSAW) steel pipe,also called HSAW pipe,welding line shape like a helix.It is using the same welding technology of Submerged Arc-Welding with LSAW pipe.Differently SSAW pipe is spiral welded where the LSAW is longitudinally welded.Manufacturing process is rolling the steel strip,to make the rolling direction have an angle with the direction of the pipe center,forming and welding, so the welding seam is in a spiral line.The SSAW pipe diameter range is from 20 inch to 100 inch, 406 mm to 2540 mm.

The technological process of welding pipes:

Uncoil the raw materials – surface flatness – end cutting and welding- looping- forming -welding- remove the welding bead – pre-correction – induction heat treatment- sizing block and correction – eddy current testing- cutting-hydraulic pressure testing- pickling- final inspection (strictly) – packaging – shipments.